Millwright Job Description

What is a Millwright Professional?

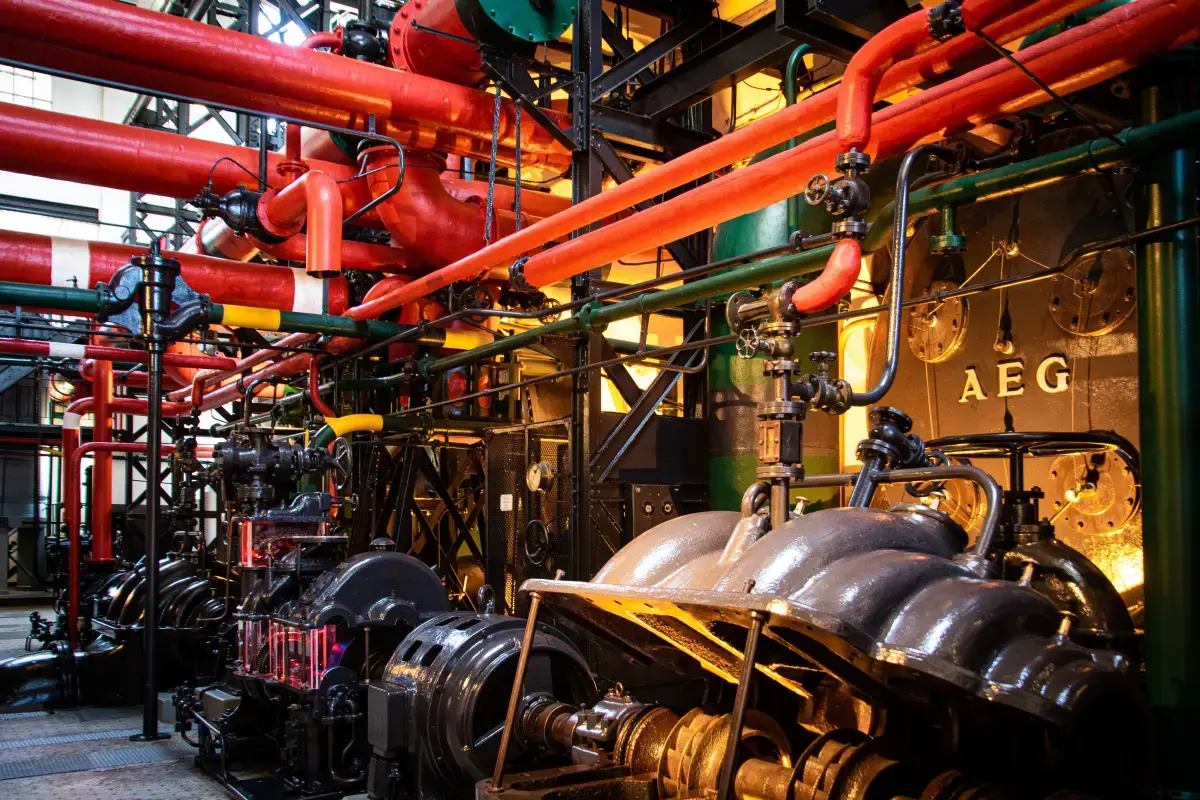

A millwright is a skilled trade that involves the installation, maintenance, and repair of industrial machinery and equipment. Millwrights typically work in factories, power plants, and other industrial settings. The duties of a millwright vary depending on the specific job, but may include installing new machinery, repairing and maintaining existing machinery, and performing routine maintenance tasks.

What does a Millwright Expert do?

Millwrights use a variety of tools and equipment in their work, including hand tools, power tools, and lifting equipment. Most millwrights have completed a formal apprenticeship program, which typically lasts four years. During their apprenticeship, millwrights learn the skills and knowledge necessary to perform their job safely and effectively.

What are the Skills of a Millwright?

A millwright is a skilled trade that involves the installation, maintenance, and repair of industrial machinery and equipment. Millwrights work in a variety of industries, including manufacturing, mining, and forestry. The most important skill for a millwright is mechanical aptitude. Millwrights must be able to understand complex mechanical systems and how they work together. They must be able to use a variety of tools to disassemble and reassemble machinery.

What makes an Expert Millwright?

Millwrights must have a strong understanding of safety procedures. They must be able to identify potential hazards and take steps to mitigate them. They must also be able to follow instructions carefully to avoid accidents. Millwrights should have a high school diploma or equivalent. Many millwrights also complete an apprenticeship, which can last up to four years. During an apprenticeship, millwrights learn the trade through on-the-job training and classroom instruction.

What level of Experience & Qualifications are required to be a Millwright?

Industry Experience: To become an expert millwright, it is recommended to have a minimum of five years of millwright experience in various industries, including knowledge and understanding of the mechanics involved in setting up, troubleshooting and maintaining heavy industrial machinery. 2. Training: Millwrights should complete extensive training on safety practices when working with hazardous materials or around heavy machinery like forklifts because such jobs can be dangerous for employees who arent adequately prepared. Additionally, detailed instruction related to problem solving basics and specifics about particular machines or systems are beneficial for successful completion of maintenance tasks as efficiently as possible—this includes hands-on practice assembling and reassembling machines and components from start to finish so that each step can become second nature. 3. Qualifications: Expert millwrights need a specialized set of skills that go beyond the basic apprenticeship requirements; qualifications should include master level certifications such as Journeyman certification through assessments administered by UBC Millwrights Union Branch 2301 or Trade Certification administered by Alberta Construction Safety Association (CSA). Additionally technical certifications in engineering technology programs offer more evidence of expertise on top-level job applications than industry school courses alone could provide–these often involve coursework covering topics related to precision measurement techniques, low voltage/high voltage electricity including diagnostics/troubleshooting , vibration analysis , hydraulics/ pneumatics , balancing & alignment tests among many others specialty areas depending on the specific workings associated with individual industrial plants . 4. Education: While having educational qualifications is not required to work as an Expert Millwright—for those seeking increasing levels of responsibility in this area– additional education may help enhance their knowledge base enabling them significantly improve their chance for success . A formal degree program from a college or university which focuses specifically on mechanical trades will be beneficial when attempting positions at higher management positions; many schools offer courses directly related mechanical engineering technology which could come as an advantage over competing candidates applying for similar roles within diversely skilled workplaces .

What is the Salary of a Millwright?

A Millwright is a skilled tradesperson who specializes in the maintenance and installation of industrial machinery and equipment. The salary of a Millwright can vary significantly, depending on experience level, geographical location and job responsibilities. Generally speaking, junior-level Millwrights can expect to earn between $25-35 per hour depending on their city. In some cases hourly wages may rise to up to $50 as junior millwrights gain more experience and become more proficient in their trade. Mid-level Millwrights typically earn between $45-$60 per hour; high levels of experience paired with extensive skill requirements draw much higher rates for these employees when hired by larger companies or plants that require hard skills such as welding or fabrication abilities rather than simply routine repair work. Some mid-level roles may even reach into the high 60’s range depending upon the skill requirements required. Senior-Level Millwrights are sought after by many businesses due to their vast expertise in installing, maintaining and repairing machines at an efficient rate while still maintaining very safe workplaces under strict timelines in demanding environments. The average senior level millright salary is estimated around $80 -$90 dollars per hour based on location as well as individual qualifications which could see experienced workers earning upwards of 100 dollars an hour particularly when taking into account any additional certifications they earned throughout the course of their career(s).

What are the Working Conditions for a Millwright?

A millwright generally works in an industrial environment or on construction sites. Working conditions can vary significantly depending on the type of job and employer, as well as on any safety considerations that may be put in place. Generally speaking, a millwright must be able to work with his or her hands for long periods of time and possess good manual dexterity. Millwrights typically stand for long periods performing their tasks, so comfortable footwear is recommended. They may need to lift heavy objects from time-to-time and bend over machinery and equipment often, so physical strength is important as well. Additional tools are needed for the millwright’s job such as wrenches, pliers, rulers, levels and hand tools like punches, hammers and screwdrivers along with welding equipment when necessary (for repair or installing parts). The individual must be trained to read blueprints since they will regularly use them while assembling machines or preparing them during repairs/maintenance processes according to manufacturer instructions/specifications. Safety glasses are usually worn due to potential dangers associated with workplace accidents (consisting of working around moving objects); protective clothing should also be worn because there might also some contact with hazardous materials; hearing protection devices can also come in handy when working around loud noises too (those coming from transport equipment such as lifts). Good temperature control systems are important since operating environment temperatures can become excessive at times; ventilation including oil mist products should help maintain a more pleasant atmosphere even when using heat treatment furnaces for example - protective masks can then become necessary based on the intensity/type of contaminants present. Also note that overtime might occasionally be required by employers depending on workload deadlines - notice needs normally given ahead before start though implying agreement from both parties priorly established through a contractual arrangement between employer/employee if part-time assignment considered applicable instead resulting then into earning additional proceeds contingent upon successful task completion /safety awareness!

What are the roles and responsibilities of a Millwright?

Read and interpret blueprints, schematics, and manuals to determine work procedures

Inspect and examine machinery and equipment to detect defects and malfunctions

Dismantle machinery and equipment using hand and power tools

Move machinery and equipment, using hoists, dollies, rollers, and trucks

Reassemble and install machinery and equipment, using hand and power tools

Align and calibrate machinery and equipment, using hand tools, levels, plumb bobs, and straightedges

Connect power supply wires to machines and equipment, and connect cables and hoses to machines and equipment

Operate newly installed machinery and equipment to verify proper functioning

Adjust functional parts of devices and control instruments

Repair or replace defective parts

Lubricate and clean machinery and equipment

Start up and shut down machinery and equipment

Set up and operate machine tools to repair or fabricate metal parts

Weld metal parts

Set up and operate printing, binding, and related machines

Perform routine maintenance on machinery and equipment

Provide consultation and technical assistance to other workers

Where can I find Millwright jobs?

- Create a profile on gigexchange and promote your Millwright skills to advertise you are Open to New Work Opportunities

- Ensure your Resume (or CV), or online work profile is up to date and represents your skills and experience. Ensure your reputation reflects your ability & attitude.

- Apply for Millwright Jobs advertised on gigexchange.

- Practise Millwright interview techniques to ensure you represent your personality and ability succinctly and confidently.

- Accept the job offer if the salary meets your expectations and the employer mission and purpose reflects your core values.

Jobs

What are the best job boards for Industrial Mechanic jobs?

How can I hire Millwright staff online for my business?

The best job board for recruiting Millwright experts is gigexchange.com. Advertise full-time, part-time or contract jobs to find, hire & recruit trusted, experienced and talented Millwright candidates near you.

Are Millwright roles in demand in 2026?

Millwright experts are still in high demand in 2026. If you are an experienced Millwright or looking to train and become one. The job market is looking strong for Millwright jobs near me.