Ironworker Job Description

What is a Ironworker Professional?

An ironworker is a tradesman who fabricates, erects, and repairs structures made of steel. Ironworkers are also known as steel erectors orRebar setters. The term "ironwork" refers to anything that is made of wrought iron, such as fences, gates, railings for stairs. There are three main types of ironworkers: structural/miscellaneous (erecting reinforcing bars [rebar] and setting precast members); ornamental (setting building facades in place); and pipeline (working on gas lines).

What does a Ironworker Expert do?

Ironworkers generally work full time hours though overtime may be common during busy periods. Night shifts may occasionally be required for night work like illuminating construction sites during darkness or lowering materials with cranes during power outages caused by storms . Working conditions vary depending on the job site but danger is always present due to working at great heights so safety precautions must always be followed.. Most employers provide training programs lasting about 4 weeks which teach new recruits basic skills necessary to perform entry-level tasks safely under the supervision of an experienced journeyperson before moving onto more complicated projects

What are the Skills of a Ironworker?

Ironworkers are construction professionals who specialize in the erection, connection and support of structural steel and iron for buildings, bridges and other structures. They use a variety of tools to connect pre-fabricated metal components together; their work is both physically demanding and dangerous. As such, an ironworker must have significant strength, stamina and courage, as well as specialized skills and training. Most ironworkers begin their careers by completing an apprenticeship program lasting four years.

What makes an Expert Ironworker?

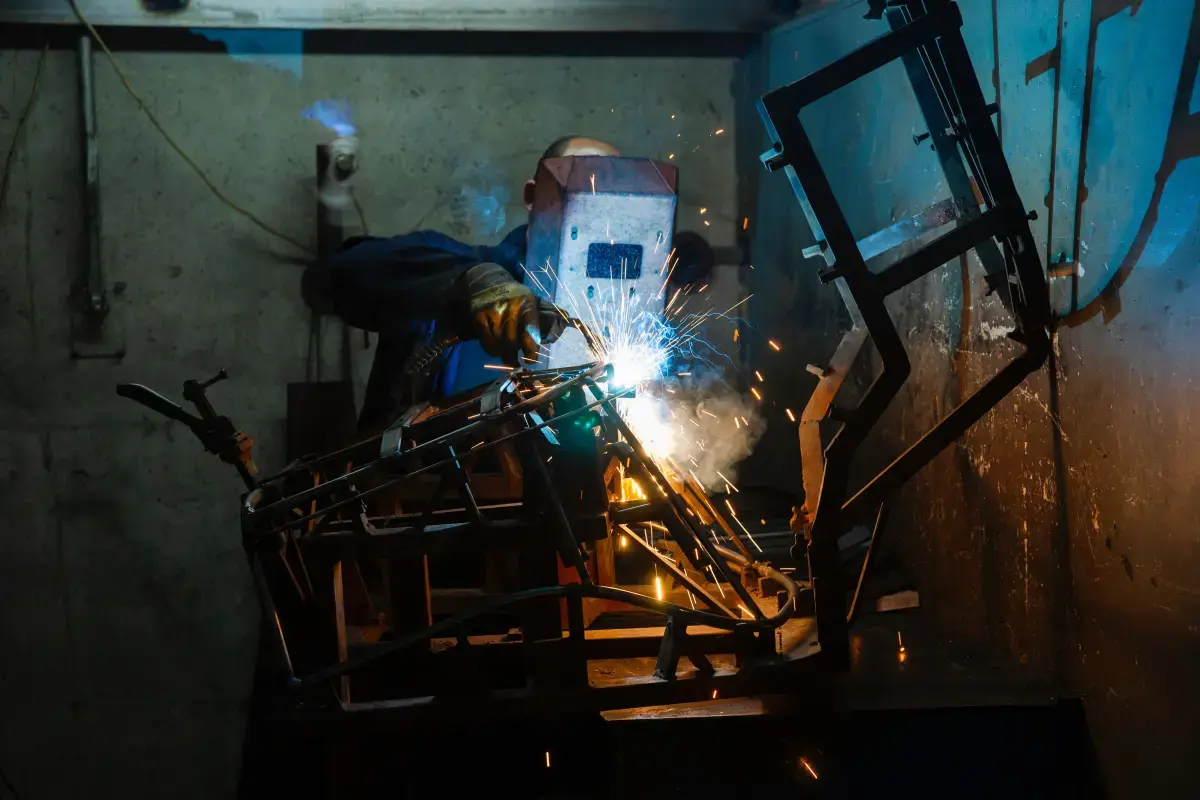

During this time they learn basic safety procedures, blueprint reading, welding techniques and rigging practices from experienced journeyman ironworkers. In addition to on-the-job training, many programs include classroom instruction in mathematics (including geometry), physics/engineering principles relevant to load bearing capacity of materials communication skills

What level of Experience & Qualifications are required to be a Ironworker?

Industry Experience: 1. At least two years of experience in all phases of ironworking, installation, fabrication and erection. 2. Ability to work with minimum or no supervision at a safe and controlled pace; be able to read and comprehend detailed education documents for assembly drawings, blueprints, diagrams etc; have knowledge of safety equipment and procedures; have a good attitude under pressure; and be willing to handle emergency repair requests onsite if necessary. 3. Must demonstrate proficiency in all aspects of design layout/fabrication process from pattern layout through welding including crane lifting operations. 4.Be able to operate hand-held power tools such as impact wrenches, air chisels/hammers & grinders (surface & shear), plasma cutters safely while adhering to OSHA guidelines.. Training: 1. State-required basic training related to the trade that covers safety protocols governing the industry in addition general apprenticeship programs designed specifically for ironworkers may also provide useful background information related the field . 2. Participation regularly scheduled trainings by employers supplemented by courses developed by trade schools are needed too sharpen skills required on any given job site help workers stay up on industry’s latest technologies processes used throughout North America Canada USA areas respectively.. Qualifications: 1. Ability interpret electrical blueprints detailing measurements bolts anchor locations clearance tolerance welds other components material strength other details used guide personnel their responsible duties duties encompass full website installations diagnostic setups serviceable area securement testing maintenance applications code violations respectively ... . 2Able demonstrate verifiable ability read specified dimensions layouts bolt placements measurement ensuring staff performs an approved procedures order fully compliance... 3Provide references customers colleagues past projects describing successful prior experiences timely performance completion consistent accurate cost effective manner preferred each jobsite circumstances respectively... 4Must possess valid state driver license clean criminal record satisfactory results drug testing undertaken respective employer course ascertaining proper employment protocol governing industrial landscape–both US CA respects.. Education: 1 High school diploma equivalent preferred degree completed courses civil engineering math science technical drawing helpful invaluable degree completion offers important benefit obtaining best paying most advanced jobs within particular field.... 2Complete related ACM certifications if available enter workforce full potential include AAMA SAiWS JAM ICPI ITMC IIW ICC NCCER CCSD endorsements appraising current skill level save money time continual updating exercise classes offered union halls public institutions community colleges national vendor program member organizations like AWS SMACNA CSTC many others associated welding professionals....... 3Volunteer extra apprenticeship tackle custom projects gain hands experience specialized engineering practices upmost priority regards certain jobs require innovative analytical measurements design schematics modern advancement fields both residential commercial infrastructures.....

What is the Salary of a Ironworker?

A junior ironworker is typically considered someone who has worked in the trade for less than two to three years and might make anywhere from $14 - $20 / hour. As their experience grows, salaries increase. At a mid-level of experience (2 - 4 years), wages can reach up to $25/hour depending on the employer and geographic area. Senior level ironworkers (5+ years) can make upwards of $30/hour or more, with some earning close to or exceeding even higher rates due to union premiums, overtime work, specialty tasks or skillsets that can enhance wages. In short a junior Ironworker may earn between 14$-20$/hour while a senior Ironrunner may earn between 25$-35$/hour at times even more as per special abilities needed or overtime based support provided.

What are the Working Conditions for a Ironworker?

Ironworkers typically work in industrial settings or job sites outdoors, often in all types of weather. They spend much of their time working on scaffolding, ladders, and aerial lifts at various heights while they install reinforcement bars (rebar) and metal grating, steel beams, pre-constructed components such as curtain walls and metal decking, which is used to construct floors and roofs. Ironworkers use a variety of hand tools including hammers/mallets; screwdrivers; a variety of wrenches; pry bars; vises; saws for circular double-headed cutting machines for beam shearing or using jumpers for drill motors for scanning metal pieces into templates. They also use electric arc welders to connect structures together permanently. Working conditions may be dangerous since there is potential exposure to hazardous materials such as asbestos dust from insulation projects that were done in the past with original building construction work. Personal Protective Equipment (PPE) must be worn by ironworkers at all times and safety measures must be taken as necessary when working with heavy machinery or heavy structural components that could cause injury if not handled properly. Overtime hours are commonly required due to project deadlines being tight or other unforeseen circumstances so extra hours are part of the job description most times over extended periods throughout certain months out of the year when demand requires them during peak seasons within construction companies specific industry sector projects need full staffing requirements completed quickly with fewer workers..

What are the roles and responsibilities of a Ironworker?

Read and interpret blueprints, drawings, and specifications to determine the layout of structural steelwork

Mark dimensions on plates or constructions

Operate various power saws and torches to cut materials according to specific measurements

erect columns, beams, girders using a crane

Fix metal framework together using bolts bars or welding equipment following engineering plans

Balance on iron grids high above ground level during construction projects in order to bolt sections of supports together and install catwalks.

Secure cables while working at extreme heights with pulleys winches rather than your hands whenever possible.

Spread load evenly when lifting heavy objects by securing them from different angles before moving them into place .Inspect completed work for any potential issues that could jeopardize safety and fix these immediately.

attaching structural steel elements (e.g., columns, beams) to each other or to a cement foundation using bolts, wires, and welding equipment

operating various types of machinery related to ironwork (e.g., forklifts, cranes)

manual labor tasks such as carrying materials and measuring distances

following safety procedures when handling dangerous materials or working at heights

inspecting completed work for quality assurance purposes

Where can I find Ironworker jobs?

- Create a profile on gigexchange and promote your Ironworker skills to advertise you are Open to New Work Opportunities

- Ensure your Resume (or CV), or online work profile is up to date and represents your skills and experience. Ensure your reputation reflects your ability & attitude.

- Apply for Ironworker Jobs advertised on gigexchange.

- Practise Ironworker interview techniques to ensure you represent your personality and ability succinctly and confidently.

- Accept the job offer if the salary meets your expectations and the employer mission and purpose reflects your core values.

Jobs

What are the best job boards for Rodbuster jobs?

How can I hire Ironworker staff online for my business?

The best job board for recruiting Ironworker experts is gigexchange.com. Advertise full-time, part-time or contract jobs to find, hire & recruit trusted, experienced and talented Ironworker candidates near you.

Are Ironworker roles in demand in 2026?

Ironworker experts are still in high demand in 2026. If you are an experienced Ironworker or looking to train and become one. The job market is looking strong for Ironworker jobs near me.